Why Choose HIPS Plastic Rolls as Your Ideal Packaging Material?

In today’s fast-evolving packaging industry, businesses are constantly looking for materials that combine cost efficiency, durability, and visual appeal. Among the many materials available, HIPS (High Impact Polystyrene) Plastic Rolls have emerged as one of the most popular choices for packaging manufacturers across various industries. Their excellent thermoforming properties, high impact resistance, and ease of customization make them the ideal solution for creating reliable, high-quality packaging.

What Are HIPS Plastic Rolls?

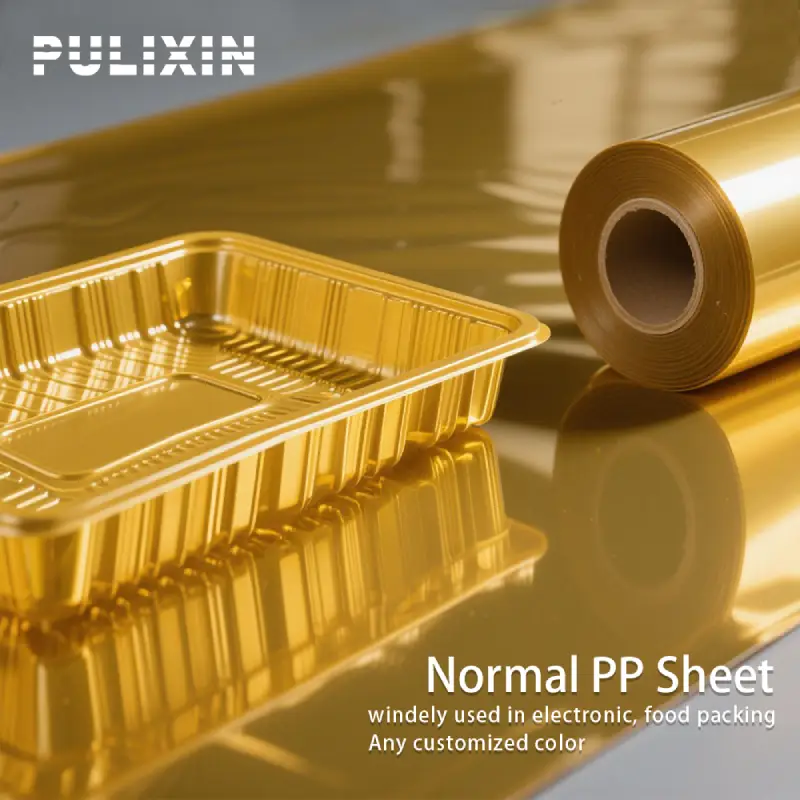

HIPS (High Impact Polystyrene) is a modified form of polystyrene designed to offer superior toughness and impact resistance. HIPS Plastic Rolls are produced through extrusion, forming smooth, glossy sheets that can be easily thermoformed into different packaging shapes.

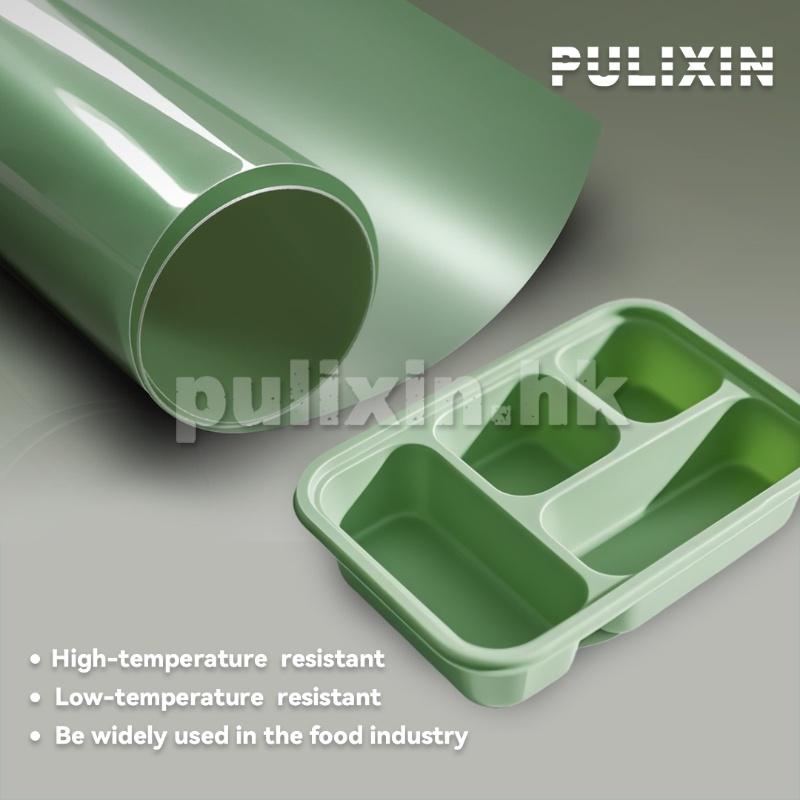

These rolls are widely used for food trays, electronic packaging, medical device containers, cosmetic boxes, and industrial product packaging, thanks to their flexibility and cost-effectiveness.

HIPS rolls come in various thicknesses and colors, including standard, anti-static, conductive, and even two-color versions — allowing manufacturers to meet the specific needs of each packaging application.

Key Advantages of HIPS Plastic Rolls

- Excellent Thermoforming Performance

HIPS is known for its outstanding forming capability. It can be easily molded into complex shapes at relatively low temperatures, which saves energy and reduces production costs.

- High Impact Resistance

Compared to standard polystyrene, HIPS provides much better shock absorption. This makes it suitable for protecting fragile items during shipping and handling.

- Lightweight and Economical

One of the main advantages of HIPS plastic rolls is their low cost relative to other plastic materials such as PET or PVC, making them a practical option for large-scale packaging production.

- Superior Printability

HIPS plastic sheets feature a smooth and uniform surface that supports high-quality printing and decoration. This enables attractive product presentation — a key factor in retail packaging.

- Easy to Process and Recycle

HIPS can be cut, laminated, printed, or vacuum-formed easily. Moreover, it is 100% recyclable, aligning with today’s sustainability goals in the packaging industry.

Wide Range of Applications

HIPS Plastic Rolls are used in a variety of industries due to their adaptability and performance advantages:

- Food Packaging – Ideal for disposable food trays, cups, and containers due to their hygienic and safe properties.

- Electronics Packaging – Anti-static HIPS rolls help prevent static damage to sensitive electronic components.

- Medical Packaging – Used for medical trays and pharmaceutical blister packs requiring hygiene and durability.

- Cosmetic Packaging – Suitable for premium product packaging with customized colors and glossy finishes.

- Industrial and Consumer Goods – Perfect for products that need rigid yet lightweight protection during transport.

HIPS vs Other Packaging Materials

While PET and PVC are common alternatives, HIPS plastic rolls offer several unique advantages:

Better impact resistance than standard polystyrene

Lower cost compared to PET

Simpler processing than PVC

Excellent surface for printing and branding

For manufacturers seeking a balance between quality, appearance, and cost, HIPS is an optimal material for thermoforming packaging production.

Why Choose Pulixin(hk) HIPS Plastic Rolls?

If you’re looking for a trusted manufacturer of HIPS Plastic Rolls, Pulixin(hk) stands out as a reliable partner.

Pulixin(hk) specializes in producing HIPS, PET, and PP plastic sheet rolls, offering a wide range of thicknesses, colors, and surface finishes. The company uses advanced extrusion equipment and strict quality control systems to ensure every roll meets international standards.

Key advantages of Pulixin(hk) HIPS Plastic Rolls:

High Quality & Consistent Thickness: Each roll undergoes precise extrusion and inspection.

Customizable Colors & Sizes: Tailored solutions for different packaging designs.

Anti-Static and Conductive Options: Ideal for electronic and industrial packaging.

Environmentally Friendly Materials: All rolls are recyclable and RoHS-compliant.

Global Export Experience: Pulixin(hk) has supplied materials to clients worldwide and provides professional logistics support.

By choosing Pulixin(hk), you gain a reliable supplier capable of supporting your long-term packaging production needs.

The Future of HIPS Packaging

With growing environmental awareness and the demand for cost-effective yet durable packaging materials, HIPS Plastic Rolls are expected to continue playing a major role in the global packaging industry.

Their ability to combine functionality, aesthetics, and sustainability positions them as a smart choice for modern manufacturers looking to optimize both performance and cost.

Whether you are producing food containers, electronic trays, or cosmetic packaging, HIPS Plastic Rolls deliver the ideal balance of quality and efficiency.

Conclusion

In summary, HIPS Plastic Rolls are transforming how packaging is designed and produced. They offer manufacturers a strong, versatile, and economical solution that meets modern packaging requirements across multiple industries.

By partnering with an experienced supplier like Pulixin(hk), you can ensure consistent material quality, faster production times, and packaging that enhances your product’s appeal and safety.

Choose Pulixin(hk) HIPS Plastic Rolls — your trusted partner for innovative and reliable packaging materials.