Wholesale China Thermoforming APET Plastic Sheet Roll - Pulixin(Hongkong) Packaging Material Co.,Ltd

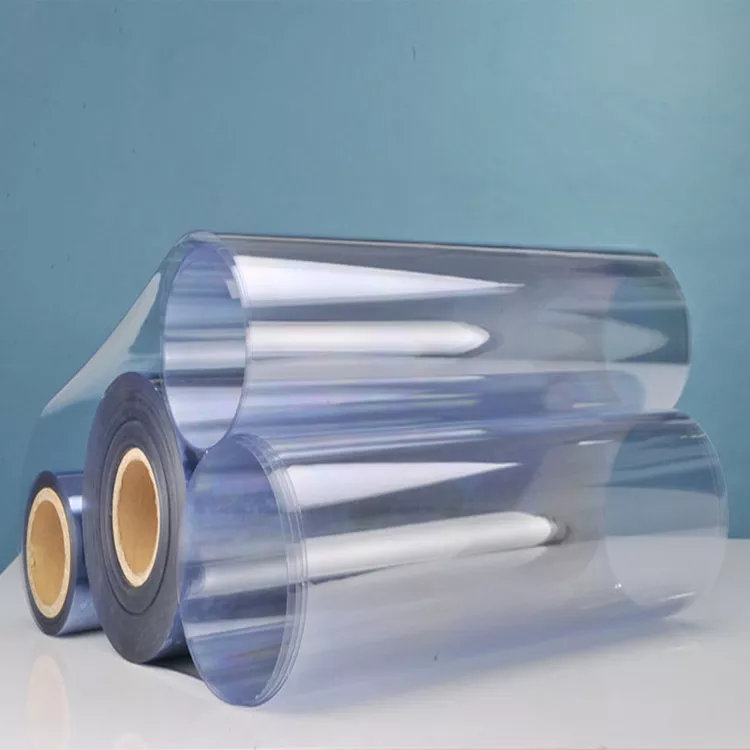

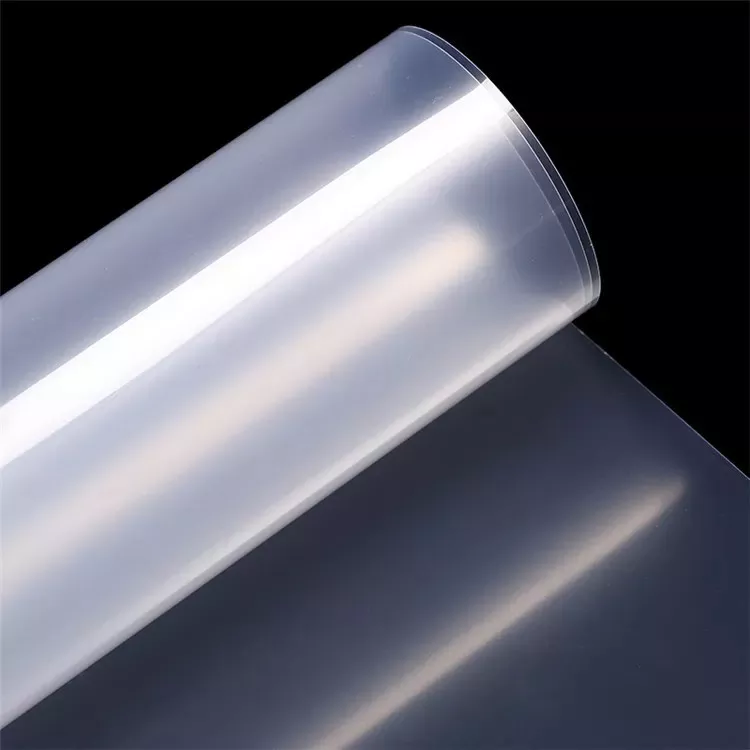

Pulixin(Hongkong) Professionally manufacture / supply / export Thermoforming APET Plastic Sheet Roll all over the world, you can custom your order in size/thickness/color/anti-static/conductive, width(300-1400mm) & thickness(0.18-2mm) are accepted, just send us your size and resistance requirement, we will send you the latest quotation ASAP.

| Name: | Rigid Thermoforming APET Plastic Sheet Roll |

| Manufacturer: | Pulixin Hongkong |

| Process: | Co-Extrusion Squeeze Out |

| Width: | PP&PS: 300-850mm / PET: 300-1400mm |

| Thickness: | 0.18-2mm |

| Packing: | Up to 150kg/Roll |

| Color: | Clear / Transparent / Black / White / Customize |

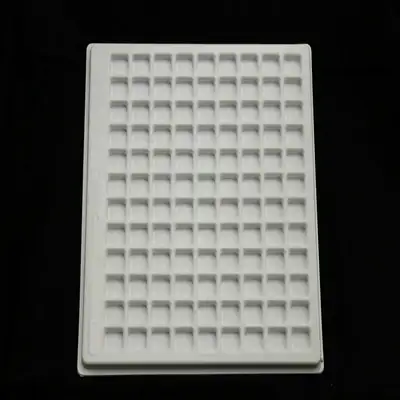

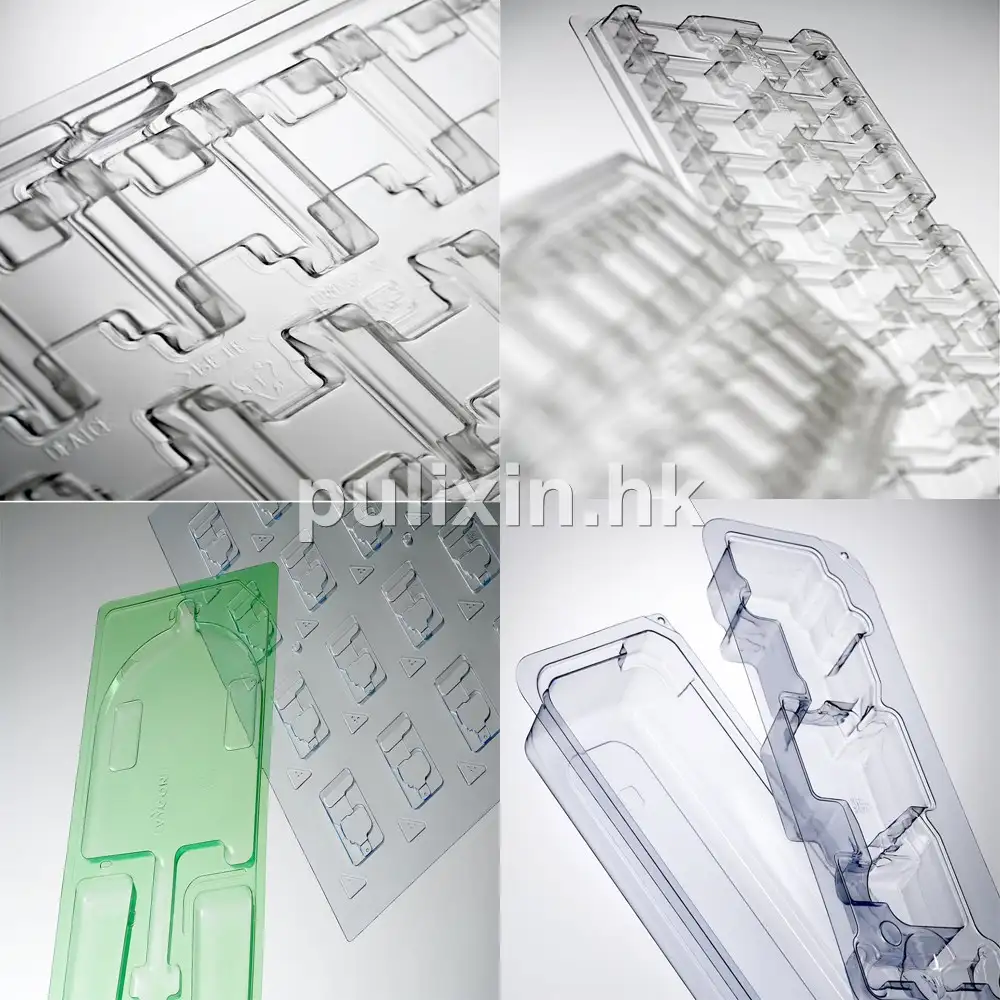

| Application: | Thermoforming Packaging / Transport Tray / Electronic Packaging /Fresh Food Packaging |

| Free-Sample: | Acceptable |

| MOQ: | 5 Tons |

Contact Pulixin

- EMAIL:

quote@pulixin.hk - PHONE:

+8615800765620

DESCRIPTION:

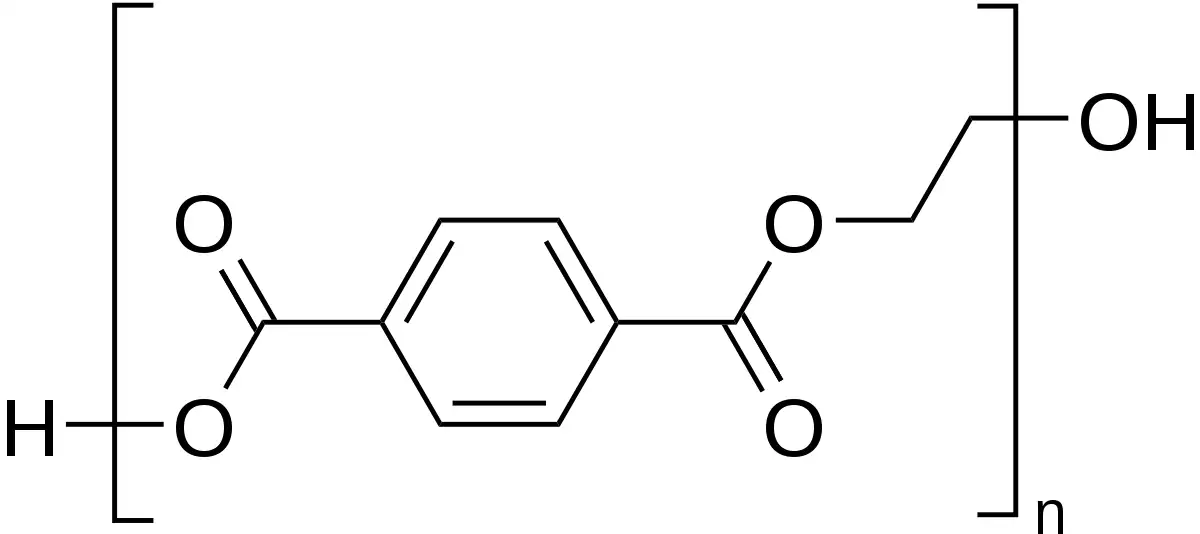

APET (Amorphous Polyethylene Terephthalate) sheet, chemically named as non-crystalline polyethylene terephthalate, is a kind of blister material. APET blister material polyester sheet is a thermoplastic environmentally friendly plastic product. Its side material and waste can be recycled. The chemical elements it contains are carbon, hydrogen, and oxygen like paper, which is a degradable plastic. After the packaging products made of this material are discarded, they eventually become water and carbon dioxide.

Typical properties OF APET

| Heat Resistance (Continuous) | 115℃ |

| Heat Resistance (Short) | 160℃ |

| Linear Thermal Expansion Coefficient | Average 23-100℃, 60*10-6m/(m.k) |

| Combusti Bility (UL94) | HB |

| Bibulous Rate (23℃ water soak for 24 hours) | 6% |

| Bending Tensile Stress | 90MPa |

| Breaking Tensile Strain | 15% |

| The Tensile Modulus of Elasticity | 3700MPa |

| Normal Strain Compressive Stress (-1%/2%) | 26/51MPa |

| Gap Pendulum Impact Test | 2kJ/m2 |

KEY FEATURES:

- Chemical Resistance

- Eco-friendly

- Stronger impact resistance

- Non-toxic

- High gloss

- low temperature resistance

- Good Thermoforming

- Suitabe for gamma ray sterilization

- High Transparency

- Easy Secondary processing

- Food Grade Plastic

- High Barrier

WHY CHOOSE USMore >>

Click to see workshop, equipment, certificated qualification and advantage strength of Pulixin(HK)- A professional PP PS PET sheet manufacturer

Not Trader But Factories

Up to 100% Virgin Material

Experience, Certification & Patent

High-standard Quality Inspection

Multiple Advanced Lines 7-12 Days Delivery

Safe Packing For International Transport

Applications:

PET sheet is a newly developed new type of plastic product, so what is the difference between it and our traditional plastic? First of all, the production process of this material is more complicated. It is produced through a series of compression polymerization processes using high-precision machinery.