Wholesale China Thermoforming GAG Plastic Sheet Roll - Pulixin(Hongkong) Packaging Material Co.,Ltd

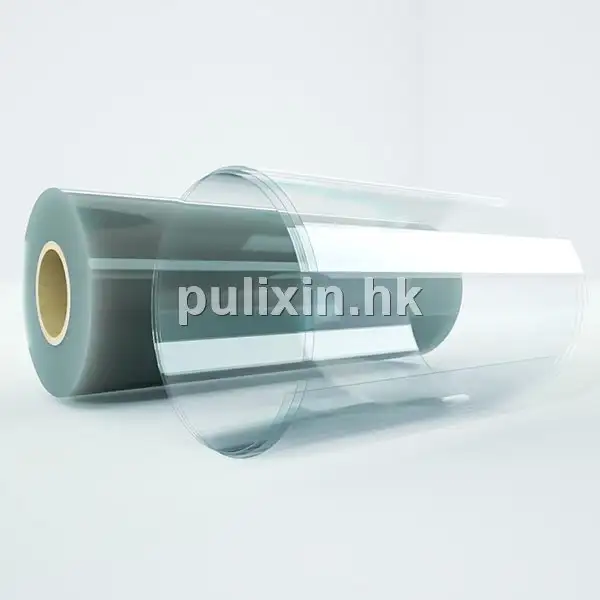

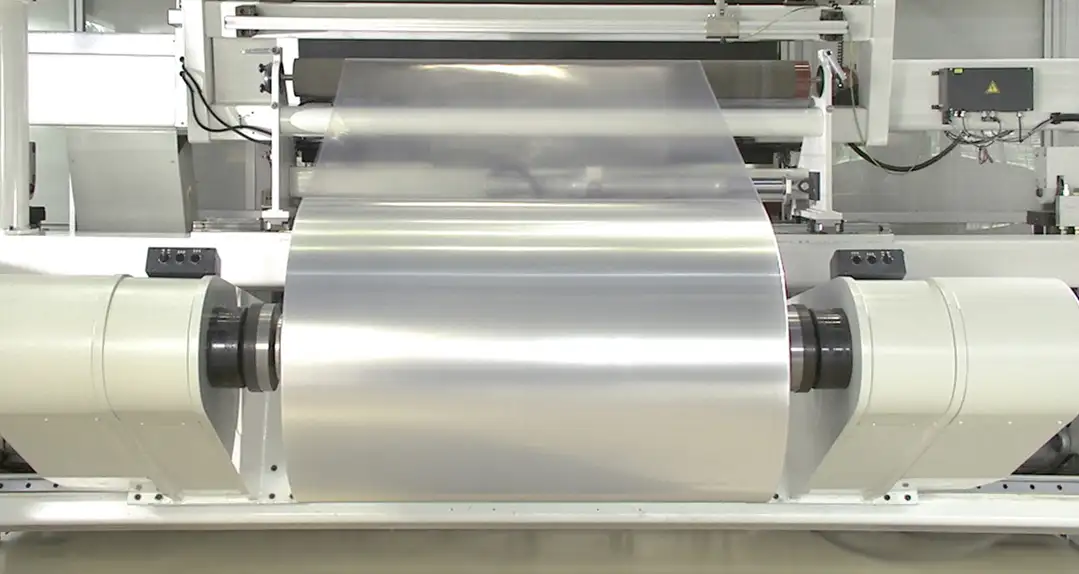

Pulixin(Hongkong) Professionally manufacture / supply / export Thermoforming GAG Plastic Sheet Roll all over the world, you can custom your order in size/thickness/color/anti-static/conductive, width(300-1400mm) & thickness(0.18-2mm) are accepted, just send us your size and resistance requirement, we will send you the latest quotation ASAP.

| Name: | Rigid Thermoforming GAG Plastic Sheet Roll |

| Manufacturer: | Pulixin Hongkong |

| Process: | Co-Extrusion Squeeze Out |

| Width: | PP&PS: 300-850mm / PET: 300-1400mm |

| Thickness: | 0.18-2mm |

| Packing: | Up to 150kg/Roll |

| Color: | Clear / Transparent / Black / White / Customize |

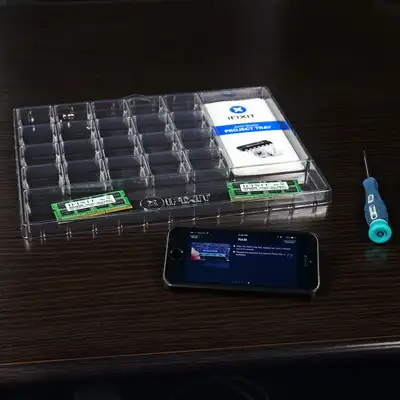

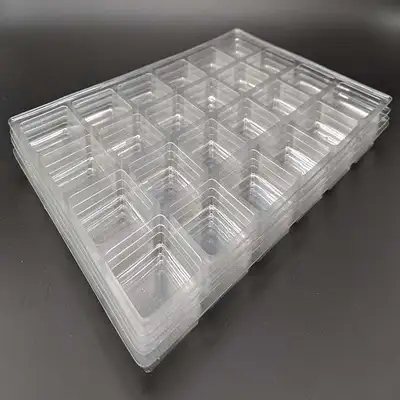

| Application: | Thermoforming Packaging / Transport Tray / Electronic Packaging /Fresh Food Packaging |

| Free-Sample: | Acceptable |

| MOQ: | 5 Tons |

Contact Pulixin

- EMAIL:

quote@pulixin.hk - PHONE:

+8615800765620

Description:

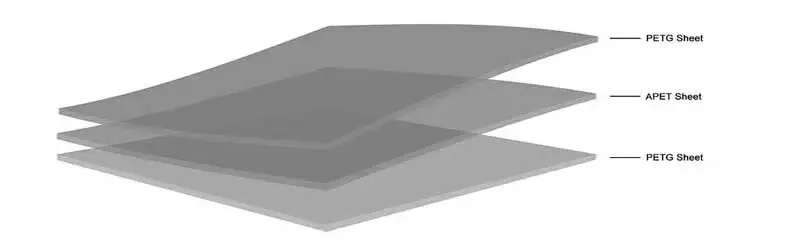

GAG sheet is a three-layer composite PET sheet. The middle layer is made of APET, and the upper and lower layers are made of PETG. The raw materials are co-extruded according to the appropriate ratio. It is especially suitable for packaging boxes that need to be bonded by high-frequency heat sealing and glue.

Parameters

| Product Name | 0.3-2mm PET ROLL |

| Material | PET, PETG |

| Color | Opaque or Tranaparent in Any Color |

| Thickness Tolerance | According to GB (higher than GB) |

| Application | Vacuum forming packaging, Printing, Bending, Folding box, Cards, |

| Reatures | – High temperature resistance, not easily melted; – Easy to peel off and no residue; – Printable, good inking effect; – Widely used in food and drug industry; |

| Special Treatmnet | Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold resistance, Heat resistance, Double-sided Matte, Conductive; |

| Sample Dliver Time | 3-7 days |

| Mass Production Time | 3-15 days depend on order quantity |

When Need To Use GAG Plastic Sheet

Multi-layer co-extrusion lamination is one of the most widely used methods in the packaging material industry to obtain packaging materials with excellent comprehensive properties. By compounding materials with different properties, a composite material with excellent comprehensive properties can be obtained. GAG type composite material utilizes multi-layer co-extrusion process, which makes the composite material have excellent impact resistance and heat sealing performance of PETG material, while the base material is relatively low-priced APET material, which makes the material have better cost performance. It can be applied in areas where APET is restricted.

KEY FEATURES:

- Easy Secondary processing

- Food Grade Plastic

- Printable

- Stronger impact resistance

- Nice mechanical properties

- High Barrier

- low temperature resistance

- pollution-free

- Recyclable

- Eco-friendly

- High gloss

- High Transparency

Parameters of Thermoforming GAG plastic sheet roll

GAG is a three-layer composite sheet. It is a three-layer composite sheet produced by co-extrusion of the middle layer APET and the upper and lower layers of PETG raw materials in an appropriate ratio. It is especially suitable for packaging boxes that need to be bonded by high-frequency heat sealing and glue. The advantages are as follows:

1, Good transparency, transparency can reach more than 90%, good texture, suitable for products requiring high transparency

2, Excellent impact resistance and rigidity, the material is hard and durable, suitable for applications with high impact resistance

3, Excellent processability. It can be processed by sawing, die cutting, drilling and laser cutting. It can also be cold bending and hot bending, bonding, welding and polishing, printing and painting; cold bending is not whitening, and the appearance is bright

4, Good thermoformability, can be molded without preheating, high precision, shrinkage rate is about 0.5%; deep formability, no cracking and uniform thickness

5, Environmental protection, can be recycled and used without polluting the environment

6, Excellent food hygiene, made of PETG, which can meet all major food regulations

WHY CHOOSE USMore >>

Click to see workshop, equipment, certificated qualification and advantage strength of Pulixin(HK)- A professional PP PS PET sheet manufacturer

Not Trader But Factories

Up to 100% Virgin Material

Experience, Certification & Patent

High-standard Quality Inspection

Multiple Advanced Lines 7-12 Days Delivery

Safe Packing For International Transport