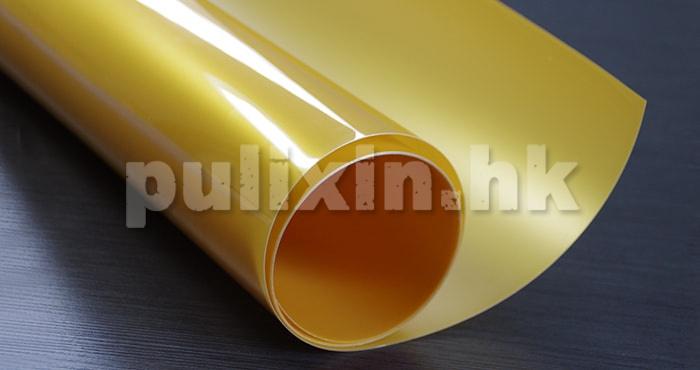

0.7mm HIPS plastic sheet rolls

Product Introduction of 0.7mm HIPS plastic sheet rolls

0.7mm HIPS (High Impact Polystyrene) Plastic Sheet Rolls are designed for applications requiring excellent impact resistance, easy thermoforming, and cost-effective performance.

Manufactured using high-quality polystyrene material, these sheets offer outstanding durability, a smooth surface finish, and consistent thickness control, making them ideal for both industrial and commercial packaging needs.

Product Advantages of 0.7mm HIPS plastic sheet rolls

- High Impact Strength

The 0.7mm thickness offers an ideal balance between flexibility and durability, ensuring strong resistance to cracking and breaking during forming or usage.

- Excellent Thermoformability

HIPS material is easy to thermoform at low temperatures, making it highly efficient for manufacturing complex shapes and detailed molds.

- Lightweight Yet Rigid

Offers excellent rigidity at a lower weight, reducing material usage and transportation costs without compromising structural integrity.

- Smooth Surface Finish

Provides a consistent, high-quality surface that is suitable for printing, lamination, or coating, ideal for branding and visual appeal.

- Food Grade Safety

Non-toxic, odorless, and compliant with food-contact regulations (on request), making it safe for food tray and packaging applications.

- Cost Effective Solution

Compared to other plastic materials, HIPS is a more economical choice for large-scale production without sacrificing performance.

- Versatile Application Range

The 0.7mm thickness is particularly suited for medium-duty packaging, disposable products, inserts, and protective packaging solutions.

- Customizable Options

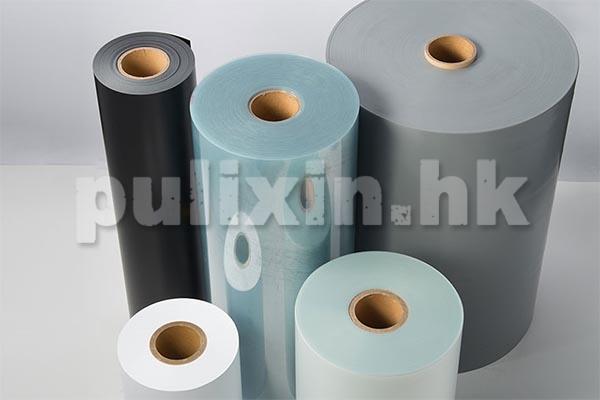

Available in various colors, widths, surface textures, and roll dimensions to meet specific customer requirements.

Product Application of 0.7mm HIPS plastic sheet rolls

- Food Packaging Trays

Ideal for forming disposable trays, plates, and containers used in fast food, supermarkets, and takeout packaging.

- Electronic Clamshell Packaging

Used to produce thermoformed clamshells and blister packs for electronic accessories, tools, and hardware.

- Cosmetic and Pharmaceutical Packaging

Suitable for inner blister trays and outer packaging for cosmetics, personal care products, and medicine kits.

- Stationery and Office Supplies

Applied in the production of document folders, report covers, and binding materials.

- Medical Trays and Inserts

Used for forming clean, durable trays and inserts for medical instruments and kits.

- Household and Industrial Storage Inserts

Used in producing custom storage dividers, tool trays, and organizing components.

Product Parameter of 0.7mm HIPS plastic sheet rolls

| Item | High Impact Polystyrene Sheet Roll, HIPS Plastic Sheet, Rgid HIPS Film |

| Brand | Pulixin (hk) |

| Origin | Shanghai, China |

| Largura | 300~850mm |

| Espessura | 0.2~2.0mm |

| Weight | 50-150kg/roll |

| Shape | Roll/Sheet |

| Material | 100% virgin |

| Cor | Black, White, Color, Natural, Transparent, Translucent. |

| Performance | Conductive, Antistatic, EOVH High barrier |

| Surface treatment | Matte, high gloss, flocking, etc. |

Product Processing of 0.7mm HIPS plastic sheet rolls

Our 0.7mm HIPS (High Impact Polystyrene) plastic rolls are manufactured through a precise extrusion process, ensuring uniform thickness, high strength, and excellent surface quality. The processing steps are as follows:

- Raw Material Preparation

Virgin HIPS resin is selected and blended with additives such as color masterbatches, UV stabilizers, or antistatic agents (as required by customers).

- Extrusion

The blended material is fed into a high-temperature twin-screw or single-screw extruder. It is melted and pushed through a flat die to form a uniform molten sheet.

- Calendering and Cooling

The molten sheet passes through a set of precision calendering rollers to achieve the desired 0.7mm thickness, surface finish (glossy or matte), and width. It is then cooled using a controlled cooling system to stabilize its structure.

- Edge Trimming and Thickness Control

Edges are trimmed to ensure clean roll sides, and advanced sensors continuously monitor thickness uniformity across the sheet.

- Winding into Rolls

The finished sheet is wound into rolls of custom width and diameter as per customer requirements, ensuring tight, wrinkle-free rolling.

- Quality Inspection

Each batch undergoes strict quality checks, including thickness measurement, impact resistance, color consistency, and surface finish inspection.

- Packaging and Storage

Rolls are packed in protective film or PE wrap and stored in a dust-free, dry environment, ready for shipment worldwide.

Why choose Pulixin(hk) 0.7mm PET plastic rolls?

- Superior Material Quality

Pulixin(HK)'s 0.7mm PET plastic rolls are made from high-quality virgin polyethylene terephthalate, ensuring excellent transparency, gloss, and durability. The material is food-grade, eco-friendly, and 100% recyclable.

- Precise Thickness Control

With advanced production lines and strict quality control, we ensure uniform thickness at 0.7mm across the entire roll. This guarantees consistent performance in thermoforming and vacuum forming processes.

- Excellent Thermoforming Performance

Our 0.7mm PET rolls offer exceptional formability, making them ideal for blister packaging, clamshell packaging, and trays. They retain shape well under heat and pressure, reducing deformation and production waste.

- High Impact Resistance

Compared to other plastics, Pulixin PET rolls provide better impact strength and shatter resistance, helping protect your products throughout the supply chain.

- Customization Available

We offer customization in width, roll length, color, and surface texture (glossy/matte/anti-fog) to meet your packaging requirements.

- Stable Supply & Fast Delivery

With a well-established production system and warehouses in China and Hong Kong, we ensure stable supply and timely delivery to global customers.

- Certified & Compliant

Our PET rolls meet international safety and environmental standards including FDA, SGS, REACH, and RoHS, making them suitable for both food and non-food packaging.