Are HIPS plastic rolls prone to static electricity?

Brief introduction

In the packaging and thermoforming industry, High Impact Polystyrene (HIPS) plastic rolls are widely used for food trays, electronics packaging, medical blister packs, toys, and various consumer products. Recently, many manufacturers and end-users have raised a common question: Are HIPS plastic rolls prone to static electricity?

Static Electricity in HIPS Plastic Rolls: A Common but Manageable Issue

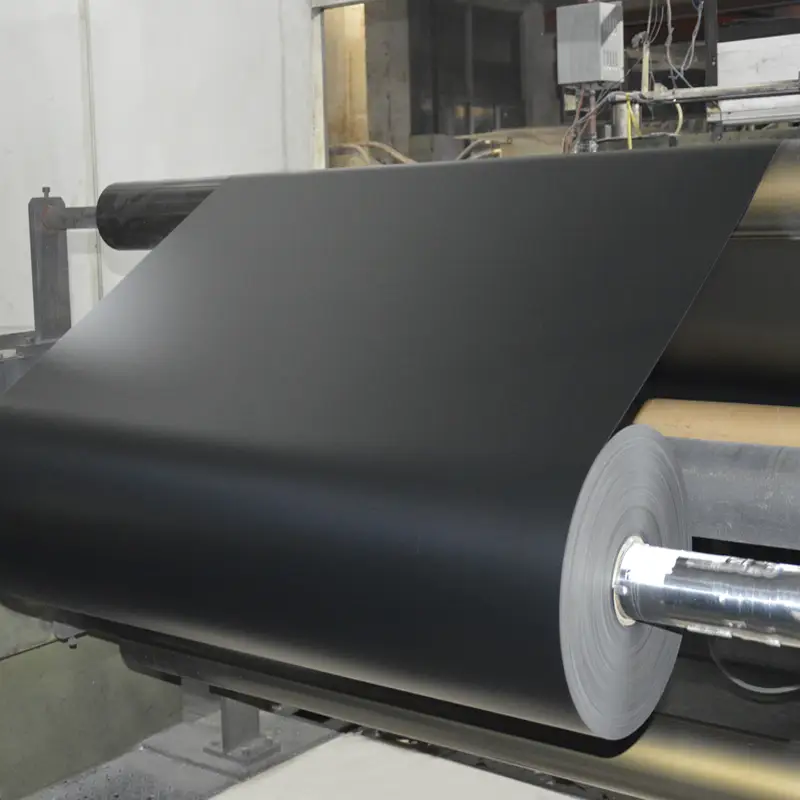

HIPS plastic roll is a versatile and cost-effective material, but like many plastic polymers, it can generate static electricity during production, cutting, or high-speed thermoforming. This occurs because the surface of HIPS tends to accumulate electrical charges when rubbed or separated from another material.

While static build-up does not affect the structural performance of HIPS sheets, it may cause certain inconveniences:

- Dust attraction on the sheet surface

- Reduced cleanliness for food or medical packaging

- Challenges in high-precision thermoforming lines

- Material sticking during stacking or processing

Fortunately, these issues can be effectively controlled with proper manufacturing technologies.

How to Optimize HIPS Plastic Rolls to Reduce Static Electricity?

1. Add Anti-Static Agents

Incorporating internal or external anti-static additives significantly reduces charge buildup. This enhances downstream processing and keeps the surface clean.

2. Improve Surface Treatment

Corona treatment or anti-static coating helps lower resistivity and enhances printability and cleanliness.

3. Optimize Production Environment

Controlling humidity and reducing excessive friction during slitting or winding minimizes static generation.

4. Use High-Quality Raw Materials

High-purity styrene and precise formulation improve stability, reducing surface charge accumulation.

5. Invest in Better Processing Technology

Advanced extrusion lines produce smoother surfaces, consistent thickness, and better performance with lower static issues.

Why PULIXIN (Hong Kong) Is a Trusted Manufacturer of HIPS Plastic Rolls?

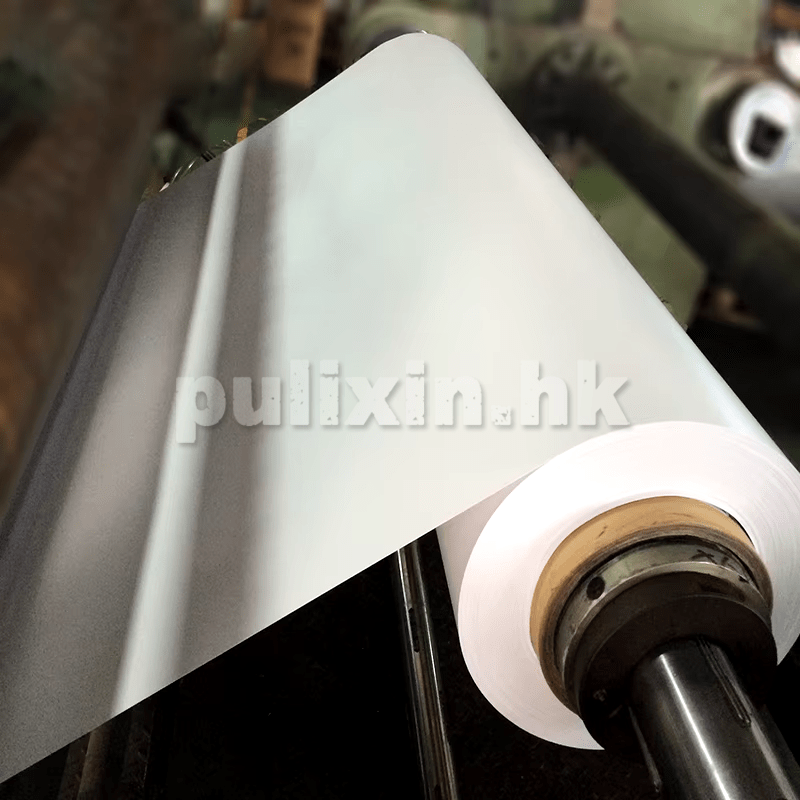

As a professional manufacturer of HIPS plastic sheet rolls, PULIXIN (Hong Kong) has built a strong reputation for delivering stable quality, competitive pricing, and reliable supply for global customers.

PULIXIN(HK) stands out because:

1. Advanced Anti-Static Solutions

PULIXIN(hk) integrates anti-static additives during production and offers customization options based on customer requirements (food packaging, electronics packaging, printing, etc.).

2. High Precision Manufacturing

State-of-the-art extrusion lines ensure uniform thickness, smooth surfaces, and excellent thermoforming performance—reducing static-related problems during automation.

3. Strict Quality Control

Every roll undergoes rigorous testing for surface resistance, impact strength, and forming performance, ensuring consistent quality in every batch.

4. Customizable Grades & Applications

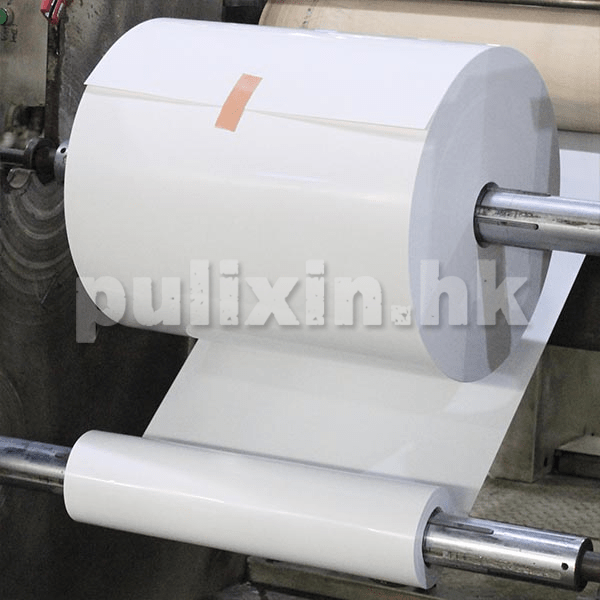

PULIXIN(hk) provides tailored HIPS plastic rolls solutions such as:

- Anti-static HIPS Plastic Rolls

- High gloss HIPS Plastic Rolls

- Food-grade HIPS Plastic Rolls

- Matte HIPS Plastic Rolls

- Colored HIPS Plastic Rolls

- Conductive or semi-conductive HIPS Plastic Rolls

5. Reliable Global Supply Chain

With efficient logistics and stable production capacity, PULIXIN(HK) supports long-term OEM/ODM cooperation with packaging, printing, and thermoforming manufacturers worldwide.

Conclusion

While HIPS plastic rolls can naturally generate static electricity, proper material formulation and advanced production techniques can significantly reduce these issues. As a reliable manufacturer of HIPS plastic sheet rolls, PULIXIN (Hong Kong) provides optimized anti-static solutions that improve performance, cleanliness, and processing efficiency.

PULIXIN remains committed to helping global customers achieve better packaging, printing, and thermoforming results with high-quality HIPS products.