Wholesale China Thermoforming PP Plastic Sheet Roll - Pulixin(Hongkong) Packaging Material Co.,Ltd

Pulixin(Hongkong) Professionally manufacture / supply / export Thermoforming PP Plastic Sheet Roll all over the world, you can custom your order in size/thickness/color/anti-static/conductive, width(300-1400mm) & thickness(0.18-2mm) are accepted, just send us your size and resistance requirement, we will send you the latest quotation ASAP.

| Name: | Rigid Thermoforming PP Plastic Sheet Roll |

| Manufacturer: | Pulixin Hongkong |

| Process: | Co-Extrusion Squeeze Out |

| Width: | PP&PS: 300-850mm / PET: 300-1400mm |

| Thickness: | 0.18-2mm |

| Packing: | Up to 150kg/Roll |

| Color: | Clear / Transparent / Black / White / Customize |

| Application: | Thermoforming Packaging / Transport Tray / Electronic Packaging /Fresh Food Packaging |

| Free-Sample: | Acceptable |

| MOQ: | 5 Tons |

Contact Pulixin

- EMAIL:

quote@pulixin.hk - PHONE:

+8615800765620

DESCRIPTION:

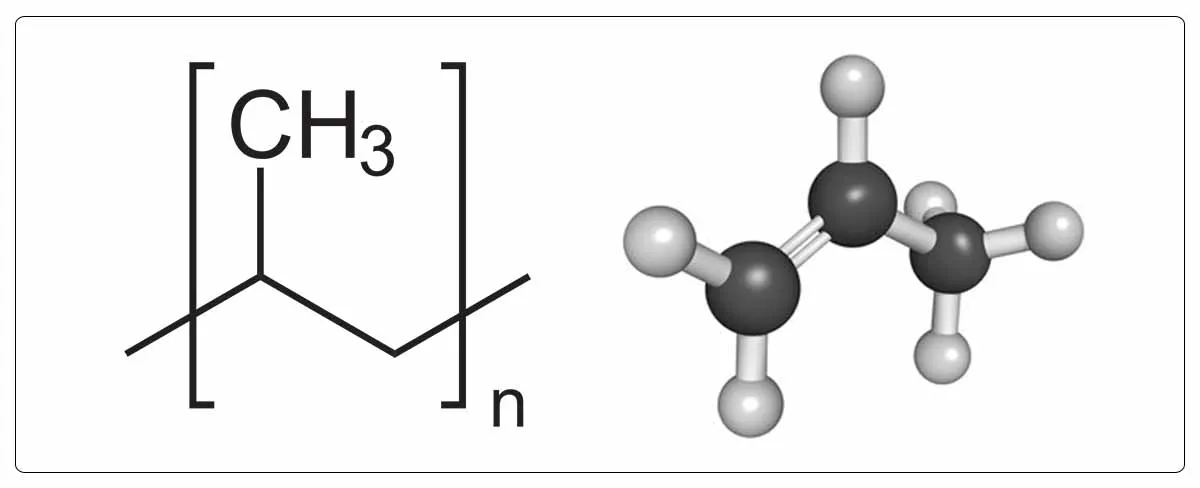

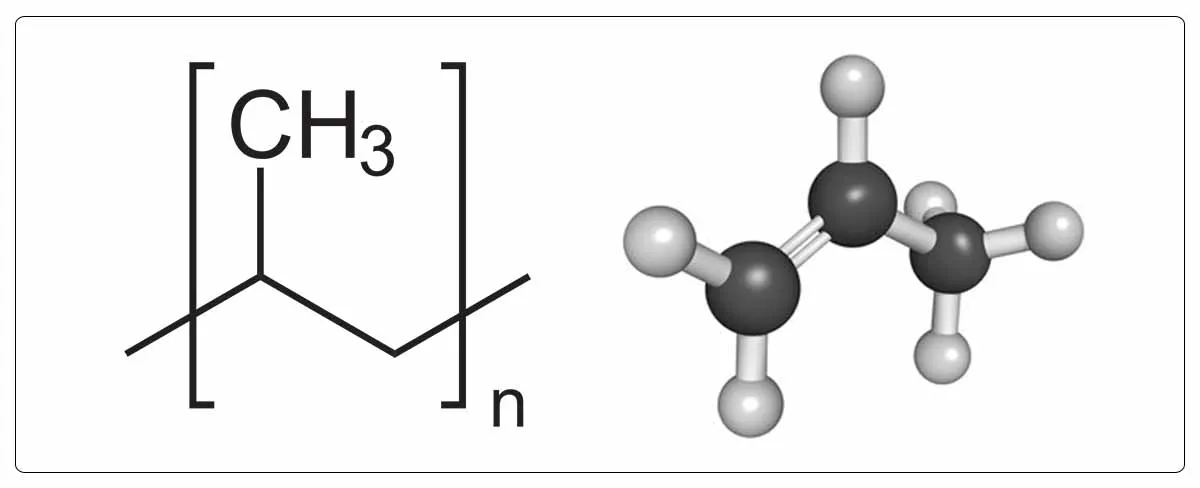

Polypropylene is the emerging alternative to other polymers for the thermoforming industry, it can withstand higher temperatures, making it thebest packaging material for both deep-freeze and microwave foods. Pulixin(Hongkong) mainly use eco-friendly polypropylene to produce PP plastic sheet for thermoforming and vacuum forming.

KEY FEATURES:

- High Transparency

- Suitabe for gamma ray sterilization

- Good Thermoforming

- Nice mechanical properties

- High Barrier

- low temperature resistance

- Non-toxic

- Printable

- Easy Secondary processing

- Chemical Resistance

- High gloss

- Recyclable

Parameters

| Density | 1.05 g/cm3 |

| Conductivity | (σ) 10-16 S/m |

| Thermal conductivity | 0.08W/(m·K) |

| Young’s modulus | (E) 3000-3600 MPa |

| Tensile strength | (σt) 46–60 MPa |

| Elongation length | 3–4% |

| Charpy impact test | 2–5 kJ/m2 |

| Glass transition temperature | 80-100℃ |

| Coefficient of thermal expansion | (α) 8×10-5/K |

| Heat capacity | (c) 1.3 kJ/(kg·K) |

| Water absorption | (ASTM) 0.03–0.1 |

| Degradation | 280℃ |

Production

WHY CHOOSE USMore >>

Click to see workshop, equipment, certificated qualification and advantage strength of Pulixin(HK)- A professional PP PS PET sheet manufacturer

Not Trader But Factories

Up to 100% Virgin Material

Experience, Certification & Patent

High-standard Quality Inspection

Multiple Advanced Lines 7-12 Days Delivery

Safe Packing For International Transport

APPLICATIONS:

PP sheet can be made into various products through thermoforming, vacuum forming,mainly used as packaging for food, medicine, medical equipment. Such as processing into jelly boxes, dairy packaging boxes, fast food boxes, cold beverage containers, trays, microwave oven appliances, etc. If processing PP sheet into blisters can be used for pharmaceutical tablets, capsules and other solid preparations packaging.