What are the applications of HIPS plastic rolls in electronic product packaging?

Application of HIPS plastic rolls in electronic product packaging

| Anmeldung | Beschreibung | Customer Pain Point Addressed | Pulinx (HK) Advantage |

|---|---|---|---|

| Protective Trays & Inserts | Thermoformed trays to hold devices and components securely | Prevents damage, scratches, and movement during transit | High impact resistance, consistent thickness, customizable shapes |

| Blister Packaging | Clear plastic blisters for retail electronics | Protects product while maintaining visibility | Durable, smooth surface, easy to thermoform |

| Component Organizers | Trays for small electronic parts (resistors, connectors, etc.) | Keeps components organized, reduces assembly errors | Precise dimensions, reliable material quality |

| Device Casings & Enclosures | Semi-finished housings for electronics | Protects electronics during shipping and storage | Lightweight yet strong, easy to form and cut |

| Anti-Static Packaging | ESD-safe HIPS for sensitive components | Prevents electrostatic discharge damage | Specialized anti-static grade, compliant with electronics standards |

| POS & Display Packaging | Retail display trays and inserts | Enhances product presentation while keeping devices safe | High clarity, smooth finish, attractive appearance |

What are HIPS plastic rolls?

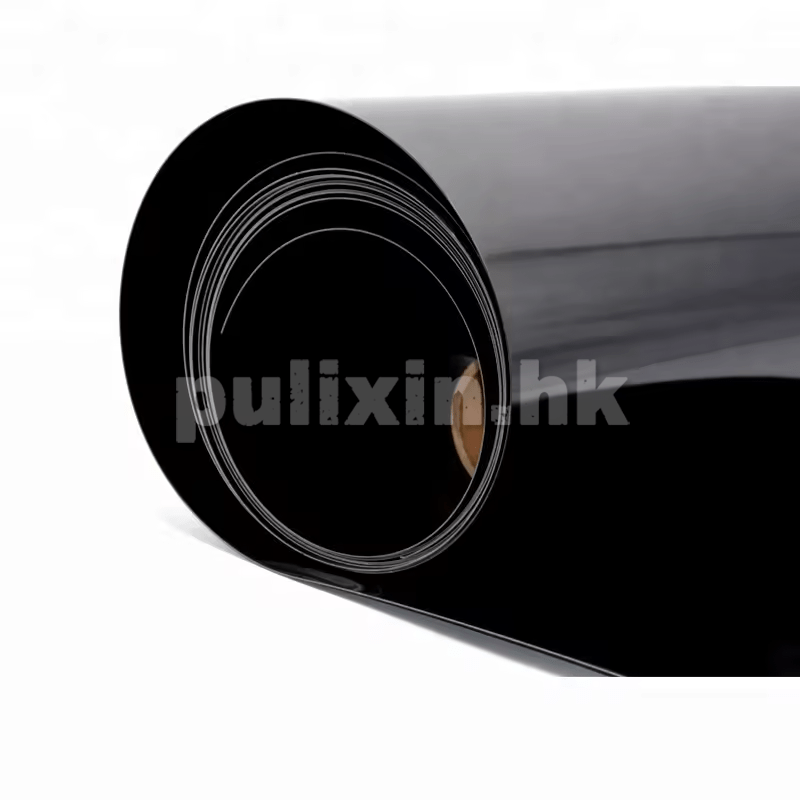

HIPS (High Impact Polystyrene) plastic rolls for electronic packaging are specialized thermoformable sheet materials designed to protect and organize electronic products and components during manufacturing, shipping, and retail display. These rolls offer high impact resistance, stable dimensions, and excellent forming properties, making them ideal for precise and protective electronic packaging applications.

Key Features for Electronic Packaging

- High Impact Strength

Protects delicate electronic components from shocks, vibrations, and drops.

- Excellent Thermoforming Performance

Easily molded into trays, blisters, clamshells, anti-static trays, and device holders.

- Anti-static & Conductive Options

Prevent electrostatic discharge (ESD) that can damage sensitive electronics.

- Dimensional Stability

Maintains consistent thickness and smooth surfaces required for precision components.

- Cost-Effective & Lightweight

Reduces packaging costs while maintaining high protection standards.

6.Typical Uses in Electronics

Component trays (ICs, PCB boards, sensors, connectors)

- Blister packages for small electronics

Protective inserts for devices (earphones, chargers, accessories)

- Anti-static trays for sensitive components

Retail display packaging for consumer electronics

Why HIPS Is Preferred in Electronic Packaging?

HIPS plastic rolls combine strength, durability, and affordability, providing reliable protection and efficient production for high-volume electronic manufacturing and packaging lines.

Why choose Pulixin (HK) HIPS plastic rolls?

At Pulixin (HK), we are committed to delivering high-performance HIPS plastic rolls that help our customers achieve safer, more efficient, and more cost-effective packaging solutions—especially for electronics, food, medical, and industrial applications. Our products stand out because we focus on quality stability, manufacturing precision, and customer-oriented service.

- Consistent Quality You Can Trust

Pulixin (HK) operates with strict production standards to ensure that every roll of HIPS plastic maintains:

- Uniform thickness

- Excellent flatness

- Smooth surface

- Reliable impact strength

This consistency ensures smoother thermoforming and reduces defects in customers’ production lines.

- Advanced Manufacturing & Material Innovation

We use advanced extrusion technology and premium-grade raw materials to produce HIPS rolls with:

- High impact resistance

- Superior thermoforming performance

- Excellent dimensional stability

Our technical expertise allows us to meet different packaging needs, from standard HIPS to food-grade, high-gloss, or colored HIPS.

- Solutions for Customer Pain Points

Pulixin (HK)’s products are engineered to solve the most common challenges faced by packaging manufacturers and electronic product suppliers:

- Damage during shipping: Strong impact resistance protects sensitive electronics.

- Inconsistent forming results: Stable material structure ensures efficient and accurate thermoforming.

- Production inefficiency: High-quality rolls reduce downtime and waste.

- ESD protection needs: Anti-static and conductive HIPS options available.

- Customization to Match Your Application

We offer tailor-made solutions to support your project requirements:

- Customized thickness, width, and color

- Surface finishes (matte, gloss, textured)

- Anti-static or conductive grades

- Small-batch trial orders available

- Reliable Supply Chain & Fast Delivery

Pulixin (HK) maintains a stable and flexible supply chain to guarantee:

- Fast order processing

- On-time shipment

- Long-term supply stability

This ensures your production schedule is never delayed.

- Professional Technical & After-Sales Support

Our team provides responsive service and technical assistance throughout the entire purchasing process—from material selection to final product application. We help customers improve their forming efficiency, reduce material waste, and optimize packaging performance.

Pulixin (HK): Your Trusted Partner for High-Quality HIPS Plastic Rolls

With advanced manufacturing capabilities, reliable quality, and a customer-first service mindset, Pulixin (HK) is dedicated to becoming your long-term supplier of HIPS plastic roll materials for electronics packaging, thermoforming trays, blister packaging, and more. For more information, please leave us a message. We look forward to your inquiry.