How to Select the Right Thickness of Anti-Static HIPS Plastic Rolls for Packaging?

Introduction

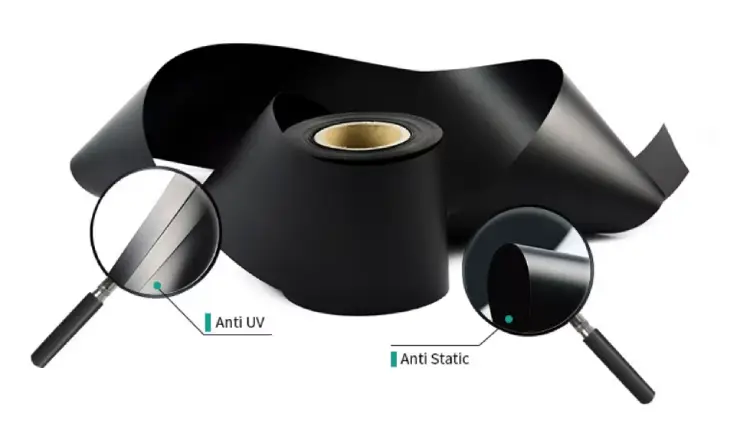

In today’s fast-paced packaging industry, High Impact Polystyrene (HIPS) plastic rolls have become a cornerstone for producing durable, lightweight, and versatile packaging solutions. Among the many variations of HIPS, anti-static HIPS plastic rolls are increasingly preferred for applications that require protection against electrostatic discharge (ESD). Choosing the correct thickness of these rolls is crucial not only for ensuring product safety but also for optimizing manufacturing efficiency and reducing material costs.

Understanding Anti-Static HIPS Plastic Rolls

HIPS is a polymer known for its impact resistance, excellent dimensional stability, and ease of thermoforming. Anti-static HIPS plastic rolls are specially formulated to prevent static electricity buildup, making them ideal for packaging sensitive electronics, optical components, and precision instruments. Unlike standard HIPS palstic rolls, the anti-static variant reduces the risk of electrostatic damage, which can lead to product malfunctions, decreased shelf life, or safety hazards during handling.

The Importance of Thickness in Packaging Applications

Thickness plays a vital role in determining the performance of HIPS plastic rolls. The right thickness ensures that the packaging provides sufficient protection, maintains structural integrity, and is compatible with thermoforming and other manufacturing processes. Using rolls that are too thin may compromise durability and result in deformation or cracking during shipping. Conversely, excessively thick rolls can increase production costs, reduce flexibility, and make forming complex shapes more challenging.

Factors to Consider When Selecting Thickness

1. Type of Product Being Packaged

The weight, size, and fragility of the product largely determine the required thickness. Lightweight items such as cosmetics or small electronic accessories may only need 0.3–0.5 mm thick rolls, whereas heavier or more fragile goods like large electronic devices, glass components, or medical equipment may require 0.8–1.5 mm thickness to provide adequate protection.

2. Thermoforming Requirements

Anti-static HIPS is commonly used in thermoforming processes to create trays, blisters, and other custom packaging forms. Thicker rolls may demand higher forming temperatures and longer cycle times, which can impact productivity. Selecting a thickness compatible with your thermoforming equipment ensures consistent quality and reduces the risk of material wastage.

3. Handling and Transportation Conditions

Packaging that will undergo rough handling or long-distance transportation needs additional strength. Thicker anti-static HIPS rolls offer enhanced impact resistance, reducing the likelihood of tears, punctures, or static-related damage during shipment.

4. Cost and Material Efficiency

While thicker rolls provide better protection, they also cost more. It is essential to balance protection requirements with cost efficiency. Many packaging manufacturers optimize thickness by conducting trials to determine the minimum gauge that still meets product protection standards.

5. Regulatory and Industry Standards

For certain applications, especially in electronics, medical devices, or food packaging, compliance with anti-static and safety standards is mandatory. Selecting a thickness that meets these standards ensures regulatory compliance and prevents potential liability issues.

Recommended Thickness Ranges for Common Applications

1. Electronics Components: 0.4–0.8 mm

2. Cosmetics and Lightweight Consumer Goods: 0.3–0.5 mm

3. Medical and Laboratory Instruments: 0.5–1.0 mm

4. Heavy Electronics or Fragile Glass Products: 0.8–1.5 mm

These ranges are general guidelines. Manufacturers often adjust thickness according to specific product dimensions, weight, and handling conditions.

Practical Tips for Choosing the Right Thickness

1. Consult us: We are professional anti-static HIPS membrane experts and can provide detailed advice based on your product type and intended use.

2. Conduct Material Tests: Sample tests allow you to evaluate forming properties, impact resistance, and static protection.

3. Consider Future Scalability: If your packaging needs may change, selecting a versatile thickness range can accommodate various products without frequent retooling.

4. Check Equipment Compatibility: Ensure your thermoforming or cutting machines can handle the selected thickness efficiently.

Benefits of Choosing the Correct Thickness

Enhanced Product Protection – Prevents damage during storage and transportation.

Reduced Waste – Proper thickness avoids product failure and scrap material.

Optimized Thermoforming Efficiency – Ensures smooth production with minimal defects.

Cost Savings – Balances material use with safety requirements.

Compliance and Reliability – Meets anti-static and regulatory standards, ensuring safe handling of sensitive items.