Are You Worried That the Anti-Static HIPS Plastic Rolls You Purchased Have Unstable Surface Resistance or Poor Anti-Static Performance?

In the packaging and electronics industries, Anti-Static HIPS (High Impact Polystyrene) Plastic Rolls play a vital role in protecting sensitive products from electrostatic discharge (ESD). However, many buyers encounter recurring challenges when purchasing from unqualified suppliers — unstable surface resistance, inconsistent quality, and short-lived anti-static effects. These problems can lead to damaged products, wasted materials, and increased production costs.

If you have experienced these frustrations, you’re not alone. Many global packaging and electronic manufacturers are now turning to Pulixin (Hong Kong) — a trusted HIPS, PET, and PP plastic sheet roll manufacturer — for stable quality, strong anti-static performance, and professional export support.

The Common Problems Buyers Face with Anti-Static HIPS Plastic Rolls

- Unstable Surface Resistance

Surface resistance directly determines the effectiveness of an anti-static HIPS sheet. If resistance fluctuates due to uneven raw material mixing or poor coating technology, static electricity may not dissipate properly, leading to static buildup and potential damage to sensitive electronic components during packaging or transport.

- Short-Term or Weak Anti-Static Effect

Many cheap products claim to have anti-static properties but lose their functionality within weeks or months. This happens when non-permanent additives are used, which gradually migrate to the surface and evaporate. As a result, the packaging loses its ESD protection and fails to meet industry standards.

- Uneven Thickness and Surface Defects

When HIPS plastic rolls are produced using low-end machines or poor-quality molds, the result is uneven sheet thickness and rough surfaces. This not only affects forming precision in vacuum forming or thermoforming but also compromises the visual appearance and structural strength of the final packaging.

- Inconsistent Quality and Delayed Delivery

Buyers in industries such as electronics, medical, and precision packaging require reliable supply and repeatable quality. Unstable delivery schedules or variations between batches can disrupt production lines and reduce efficiency.

The Solution: Partner with Pulixin (Hong Kong)

The most effective way to avoid these problems is to work with a factory-qualified manufacturer that has proven experience, advanced production lines, and strict quality management.

That’s where Pulixin (Hong Kong) comes in.

As a professional manufacturer specializing in Anti-Static HIPS, PET, and PP Plastic Sheet Rolls, Pulixin has earned a strong reputation for high precision, stable anti-static performance, and consistent product quality. The company operates multiple modern production facilities and serves clients across Asia, Europe, and the Americas with customized plastic packaging materials.

Why Choose Pulixin (Hong Kong) for Anti-Static HIPS Plastic Rolls?

- Reliable and Long-Lasting Anti-Static Performance

Pulixin’s anti-static HIPS plastic rolls are designed with stable surface resistance ranging from 10⁶ to 10⁹ ohms, providing reliable ESD protection. The anti-static agent is evenly distributed during the extrusion process, ensuring durable and long-lasting performance that won’t fade over time or with environmental changes.

- Advanced Production Equipment

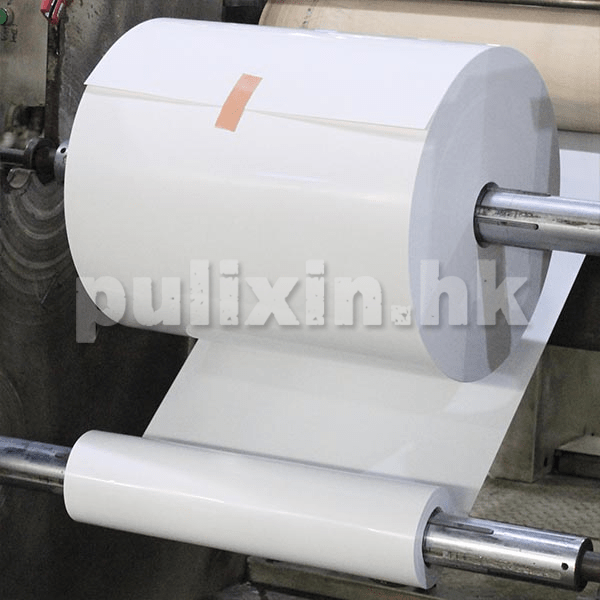

Pulixin uses high-precision co-extrusion lines equipped with automatic thickness control systems. This technology guarantees uniform sheet thickness, smooth surfaces, and excellent thermoforming performance — ideal for applications such as electronic trays, medical packaging, and industrial blister packs.

- Strict Quality Control

Each batch of Pulixin anti-static HIPS sheet rolls undergoes rigorous testing for:

- Surface resistance stability

- Tensile and impact strength

- Thickness uniformity

- Visual appearance and forming behavior

Pulixin provides full quality inspection reports and technical data sheets to ensure complete transparency and confidence in every shipment.

- Flexible Customization Options

Pulixin understands that different industries have unique requirements. That’s why the company offers customized thickness, color, width, and resistance levels.

- Available options include:

- Permanent anti-static type

- Coating anti-static type

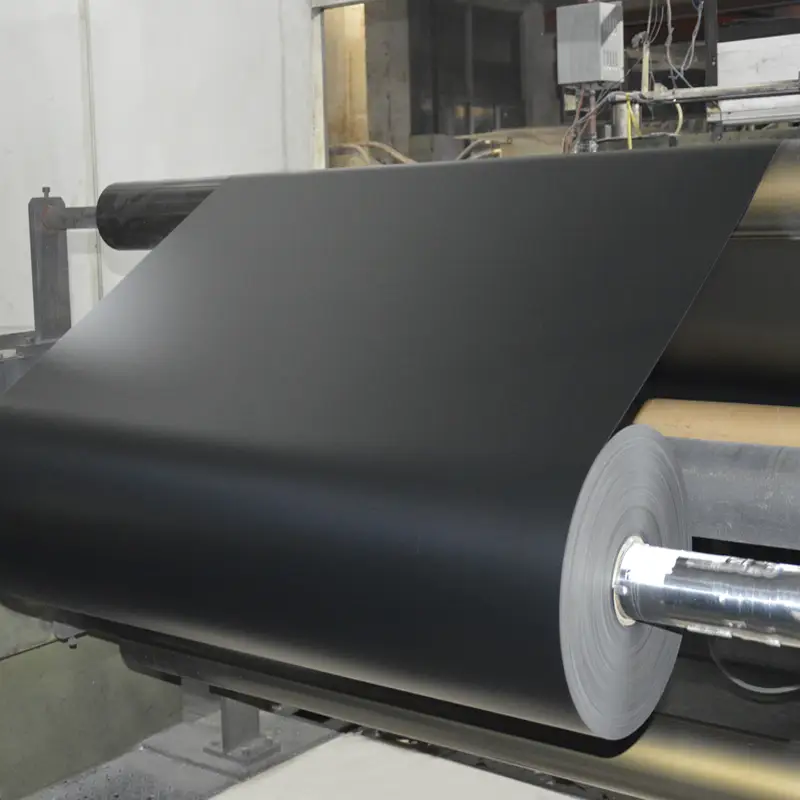

- Conductive black HIPS rolls

Custom colors (transparent, milky white, black, etc.)

This flexibility allows customers to choose materials that perfectly match their product protection and packaging design needs.

- Strong Production Capacity and Fast Delivery

With a monthly capacity exceeding 2,000 tons, Pulixin ensures stable and continuous supply for both domestic and export markets. Thanks to its Hong Kong office and mainland China factories, Pulixin provides fast lead times and efficient logistics support, helping customers maintain smooth production schedules.

- Global Export Experience

Pulixin (Hong Kong) has built long-term partnerships with packaging manufacturers and electronic component suppliers across Asia, Europe, the Middle East, and the Americas. The company’s strong international trade experience ensures hassle-free export procedures, including documentation, shipment tracking, and after-sales support.

Applications of Pulixin Anti-Static HIPS Plastic Rolls

Pulixin’s anti-static HIPS sheet rolls are used in a wide range of industries, including:

- Electronic packaging (IC chips, sensors, PCBs, connectors)

- Medical and pharmaceutical trays

- Automotive electronics packaging

- Industrial and precision component packaging

- Smart device and semiconductor blister trays

Because of their excellent thermoforming ability, stable resistance, and superior mechanical strength, Pulixin’s materials help customers improve packaging reliability and product protection efficiency.

Eco-Friendly and Sustainable Manufacturing

Pulixin not only focuses on product quality but also on environmental responsibility. The company follows strict environmental management procedures and uses recyclable and RoHS-compliant raw materials. Its anti-static HIPS rolls can be recycled and reused, reducing environmental impact and aligning with the sustainability goals of modern packaging companies.

Pulixin’s Commitment to Quality and Customer Success

At Pulixin, customer satisfaction is the top priority. From product consultation to technical guidance and after-sales service, the Pulixin team ensures every client receives prompt responses, tailored solutions, and stable support.

Pulixin is not just a material supplier — it is a trusted packaging partner helping customers around the world achieve higher efficiency, better performance, and long-term success.

If you’ve been disappointed by suppliers whose anti-static HIPS plastic rolls show unstable surface resistance or short-lived anti-static performance, it’s time to switch to a trusted and proven manufacturer.

Pulixin (Hong Kong) delivers what others promise:

- Stable anti-static performance

- Consistent thickness and surface quality

- Reliable supply chain

- Professional international service

With advanced production technology, strict quality management, and a commitment to global standards, Pulixin ensures that every roll meets the highest expectations of precision packaging industries.Please contact us for more information.